Through feed press lines

ORMAMACCHINE THROUGH FEED PRESSING LINES

Planned and executed on modular basisORMAMACCHINE pressing plants are ideally divisible by four successive working stages.

1) LOADING

Three alternatives are available:

A) panel lifting platform with pusher;

B)

up-down panel infeeder by vacuum (max thickness 8 mm);

C) overpassing up-down vacuum infeeder and roller conveyor.

2) PRELIMINAR TREATMENT STAGE

While passing to the pressing unit, panels are operated by the

following machines:

A) brushing unit;

B) high definition glue spreading system;

C) ennobling surface laying over device;

D) disc, roller, belt conveyor arrangements for transfering, tilting or

overturing.

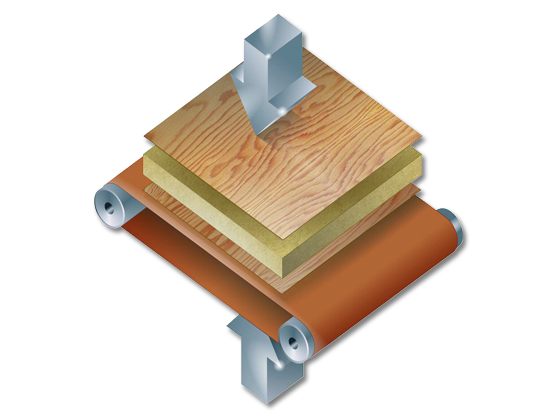

3) PRESSING UNIT

Located in the centre of the line the hydraulic press features:

A) pantographated structure;

B) drilled solid steel platens;

C) piston prefilling hydraulic system;

D)

thick chromed pistons;

E) heating plant.

4) OUTFEEDING

In final phase the following unloading systems are available:

A) idle wheel conveyor;

B) up-down stacker;

C) overpassing bridge unloader by

vacuum;

D) other conveying or positioning systems.