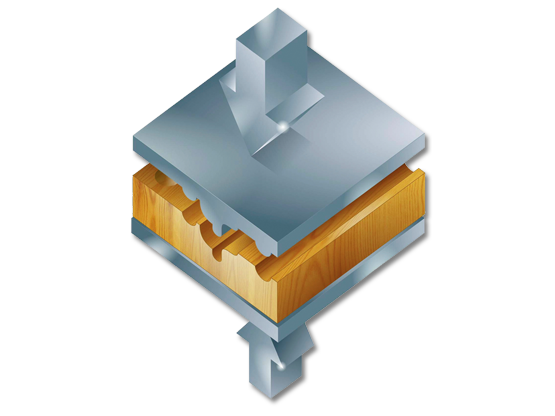

Embossing presses

• Ormamacchine embossing presses hold our great experience achieved in thirty year design and specific production so to grant reliable models and a right mix between price and technology.

• The machine structure is made by very

thick, certified iron , milled plates without welding granting the max mechanical tightness.

• The hydraulic installation, designed by Ormamacchine, is able to obtain the constant working pressure from 35 to 100 kg/cm2. The

pressure is perfectly adjustable to make the machines fit any type of working.

• The solid drilled steel platens are heated up by electric resistances or by thermal oil at max 250 °C, even in this case, it is possible to settle any

intermediate value.

• The platen dimensions change from the smallest version - 600 x 350 mm – to the biggest model whose working dimensions are 2500 x 1300 mm. Upon request, it is possible to produce machines with special

dimensions.

• The platens are supplied with standard drilling on the two diagonals to fix the moulds whose costs are always excluded from the machine prices.

• Security mechanical and electric systems grant high standards,

indeed our machines comply with all international working safety rules in force.

• The control board holds all the machine functions , the operator is able to set all paramethers necessary for the production such as: working

pressure, pressing time, number of pressing operations, degassing cycle, platen opening, carving depth programming, working temp and so on.

• These machines are supplied in dowstroke or upstroke desing (upon request).