Membrane Presses

The Ormamacchine’s membrane presses for shaped surfaces covering, are born from the experience acquired by the company in this particular type of process.

A full range of presses has been developed, with and without membrane, with 3 different systems of work:

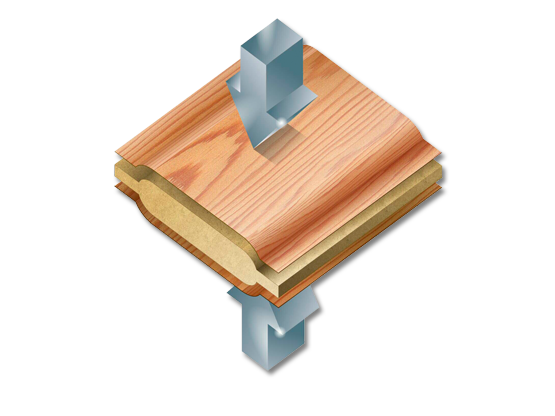

1 OIL + MEMBRANE

Membrane forming press equipped by a revolutionary working process PATENTED) for shaped

panels covering with both PVC film and natural wood veneer.

Very low energy consumption, self-levelling of the liquid in the tank, depending on the size of the panels, absolute safety against the heating liquid leakage, simultaneous and automatic loading and unloading, high specific pressure (20

Kg / cm ²), ease of use, make this machine unique.

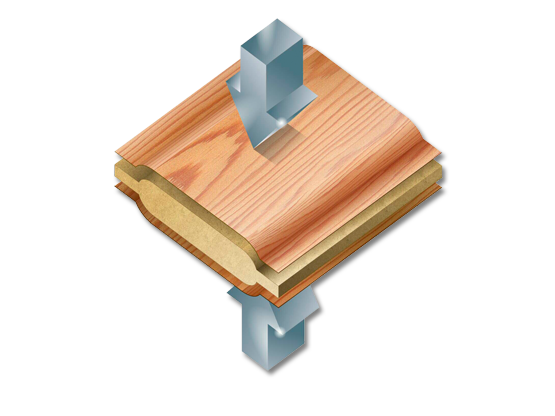

2) AIR WITHOUT MEMBRANE

This press is suitable for shaped panel covering with PVC film and transfer material.

The principle of operation doesn’t require the use of the membrane, this also allows the coating of particularly hard shapes, and also eliminates the costs related to the replacement of the membrane

The possibility to reach very high temperatures (up to 170 ° C), allows the use of this machine also for the coating with plastic materials that require high temperatures for their moulding, (i.e. ABS)

A same side loading / unloading system, by means of two trays, allows the "dead time" elimination and the management of the entire system by even a single operator.

The entire plant is controlled by a programmable logic controller (PLC), which allows the setting from the control panel all the work functions such as:

- Press pre-heating

- Working temperature

- Pre-heating

time

- Pressing time

- Min. pressure during the pre-heating

- Max working pressure

- Loading group speed

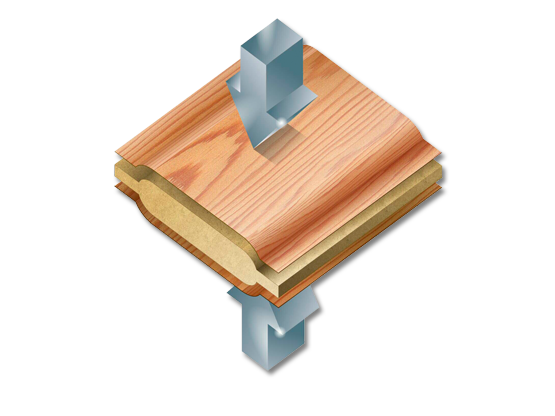

3) AIR + MEMBRANE

This press is suitable for shaped panel covering with PVC film and

natural wood veneer.

Membrane use is needed only for natural wood veneer gluing.

The machine is equipped with a membrane fasten/unfasten quick system that allows to shift from one working system to the other in few minutes.

Even this plant, as the previous one is controlled by a programmable logic controller, which allows the setting of the variables listed above directly from the control panel.

The entire range of membrane presses has immediately achieved considerable success, affirming itself on the market, both for its own peculiarities: lower operating costs, increased productivity, safety, and because, despite offering

much more than traditional membrane presses, it is very competitive in terms of price.